Flow Control Trainer (Computer Controlled System)

Flow Control Trainer (Computer Controlled System) Specification

- Usage

- Laboratory

- Material

- Metal

- Voltage

- 220 Volt (v)

- Equipment Materials

- Brass

- Type

- Flow Control

- Temperature Range

- 60 Celsius (oC)

Flow Control Trainer (Computer Controlled System) Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Australia, North America, Central America, Eastern Europe, Africa, Middle East, South America, Asia

- Main Domestic Market

- All India

About Flow Control Trainer (Computer Controlled System)

The present set-up is designed to study a PID Controlled Flow Process in the industry. Water is pumped from the sump tank by means of a centrifugal pump to a Pneumatic Control Valve and after passing thorough the Rotameter it return back to the sump. The Differential Pressure transmitter with an Orificemeter is fitted in the water line. The flow of water in the line is sensed by the transmitter and communicated to the digital indicating controller. This measured variable is compared with the Set Point by controller and output is generated and given to I/P converter, which in turn supply the 3-15 Psig pressure to vary the opening of the Pneumatic control valve to eliminate the error observed. As the opening of pneumatic control valve varies, the flow of water in the line gets effected. This process goes on until the Set Point target is achieved. A ball valve is also provided in the water line to disturb the system and to observe the effect of disturbance. As the water returns in the sump tank again, the system operates in close circuit. Provided Rotameter enables to get the direct reading of flow of water in the line. These units along with necessary piping are supported in a well-designed housing and are fixed on base plate.

EXPERIMENTATION :

- To study the open loop or manual control

- To study the proportional control

- To study the two mode (P+I) control

- To study the two mode (P+D) control

- To study the three mode (PID) control

- To study the tuning of controller (Open loop method) using Zeigler-Nichols method.

- To study the stability of the system using the BODE PLOT.

- Auto Tuning

Advanced Laboratory Training

The Flow Control Trainer supports foundational and advanced studies in fluid mechanics, making it ideal for universities and research labs. Equipped with computer control, users can carry out experiments with greater accuracy and record comprehensive data for analysis. Its robust construction ensures longevity, while easy integration facilitates effective practical learning and research.

Durable Materials and Reliable Design

Engineered mainly from high-quality metal and brass, this system promises resilience in demanding laboratory settings. The components are selected to resist corrosion and withstand sustained operation at up to 60C, ensuring consistent performance with minimal maintenance. Its design encompasses both safety and reliability, meeting international standards.

FAQs of Flow Control Trainer (Computer Controlled System):

Q: How does the Flow Control Trainer benefit laboratory users?

A: The Flow Control Trainer enables users to conduct accurate and repeatable experiments on fluid flow, fostering hands-on learning and enhancing research capabilities. Computer control allows for precise adjustments, data collection, and automated monitoring, increasing efficiency and reducing manual errors.Q: What materials are used in the construction of the Flow Control Trainer?

A: The trainer is constructed mainly from robust metal, with critical equipment parts made from brass. These materials enhance durability, resist wear, and ensure reliable operation within laboratory settings.Q: When should the Flow Control Trainer be used in academic settings?

A: It is best deployed during lab sessions related to fluid mechanics, process engineering, and instrumentation. The device supports both introductory and advanced coursework and is particularly valuable for experimental demonstrations and project research.Q: Where is the Flow Control Trainer manufactured and supplied from?

A: This system is manufactured, exported, and supplied from India, meeting global quality benchmarks and serving clients in academic and research institutions internationally.Q: What is the process for operating the Flow Control Trainer?

A: Operation involves connecting the trainer to a 220 Volt power source, setting up the desired temperature (up to 60C), and managing fluid flow parameters using the computer interface. Data can be logged and analyzed for educational or research purposes.Q: How is the Flow Control Trainer used in laboratory experiments?

A: In lab experiments, the trainer enables students and researchers to regulate and measure flow rates, observe system responses to various controls, and collect data for analysis. The computer-controlled system simplifies experiment execution and enhances repeatability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Process Control & Instrumentation Lab. Category

Time Constant of Thermocouple & Thermometer

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Temperature Range : 40 Celsius (oC)

Material : Metal

Equipment Materials : Constant of Thermocouple

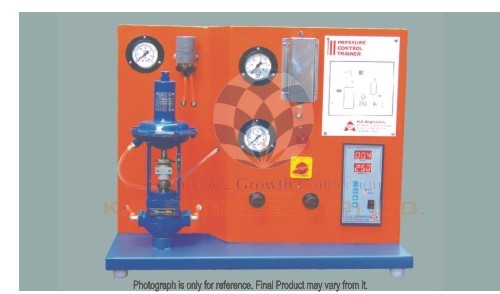

Pressure Control Trainer (Computer Controlled System)

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Temperature Range : 70 Celsius (oC)

Type : Control Trainer

Two Tank Non-interacting System

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Temperature Range : 35 Celsius (oC)

Material : Metal

Type : NonInteracting

Equipment Materials : PU

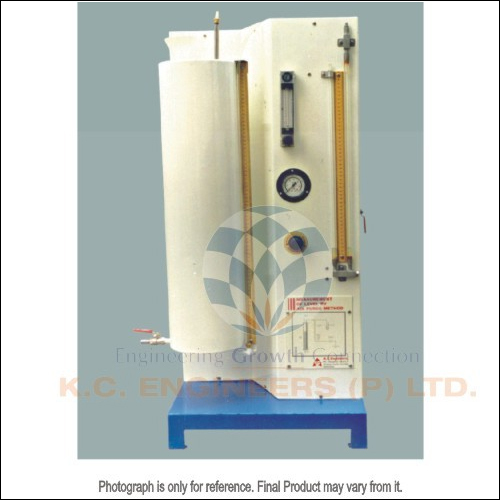

MEASUREMENT OF LEVEL BY AIR PURGE METHOD

Minimum Order Quantity : 1 Inch

Usage : Laboratory

Temperature Range : 50 Celsius (oC)

Material : Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS