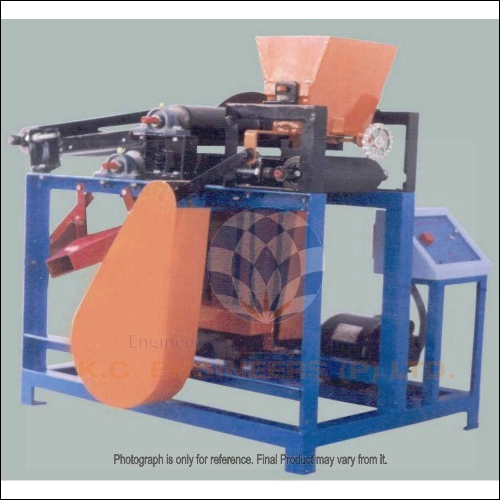

PLATE and FRAME FILTER PRESS

PLATE and FRAME FILTER PRESS Specification

- Voltage

- 220 Volt (v)

- Color

- Red and Blue, Silver

- Material

- Iron

- Power

- 500 Watt (w)

- Usage

- Laboratory

- Equipment Materials

- SS

- Display Type

- Analog

PLATE and FRAME FILTER PRESS Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Central America, Africa, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

About PLATE and FRAME FILTER PRESS

DESCRIPTIONPressure filters can apply a large pressure differential across the septum to give economically rapid filtration with viscous liquids or fine solids. The most common types of pressure filters are filter press. A filter press contains a set of plates designed to provide a series of chambers or compartments in which solids may collect. The plates are covered with a filter medium such as canvas cloth. Slurry is admitted to each compartment under pressure liquor passes through the canvas cloth and out a discharge pipe leaving a wet cake of solids behind. Plates and frames sit horizontally in a metal rack with cloth covering the face of each plate and are squeezed tightly together by a screw. Slurry enters at one end of the assembly of plates and frame. It passes through a channel running lengthwise through one corner of assembly. The set up consists of seven plates and six frames. Frames are covered with filter cloth. Feed is fed by gear pump at the top and filtrate collected at the bottom from each plate by operating the cock. After removing Cake washing and cleaning can be done by water provided by overhead tank. Inlet and outlet pressures are measured by pressure gauges. Rate of filtrate removals is measured by calibrated tank provided.

EXPERIMENTATION

To study the operation of filter press in the laboratory.

To evaluate specific cake resistance and medium resistance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Operation Lab. Category

Thickner Instroments

Minimum Order Quantity : 1 Piece

Voltage : 230 Volt (v)

Material : Iron

Power : 500 Watt (w)

Equipment Materials : SS

Usage : For Industry

Magnetic Separator

Minimum Order Quantity : 1 Unit

Voltage : 220 Volt (v)

Material : Iron

Power : 1000 Watt (w)

Equipment Materials : SS

Usage : For Laboratory

Mineral Jig

Minimum Order Quantity : 1 Unit

Voltage : 220 Volt (v)

Material : Metal

Power : 500 Watt (w)

Equipment Materials : Brass

Usage : For College

Bucket Conveyor

Minimum Order Quantity : 1 Unit

Voltage : 220 Volt (v)

Material : Iron

Power : 500 Watt (w)

Usage : For College Labs

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free