Water Purification Pilot Plant

Water Purification Pilot Plant Specification

- Temperature Range

- 5C to 50C

- Core Components

- RO Membrane, High Pressure Pump, Pre-filters, Control Panel

- Measurement Range

- TDS 50-2500 ppm

- Power Source

- Electric

- Model No

- WPPP-01

- Feature

- Skid Mounted, Easy Installation, Low Maintenance

- Accuracy

- Up to 99% Purification Efficiency

- Voltage

- 220-380 V

- Capacity

- 500-2000 LPH (liters per hour)

- Frequency

- 50 Hz

- Automation Grade

- Semi-Automatic

- Equipment Materials

- Stainless Steel (SS316/SS304)

- Type

- Water Purification Pilot Plant

- Usage

- Industrial/Research Water Treatment

- Display Type

- Digital

- Dimension (L*W*H)

- 1800mm x 1200mm x 1800mm

- Weight

- Approx. 400-800 Kg

About Water Purification Pilot Plant

Introduction:

The activated sludge pilot plant consists of an oxidation reactor, of a settler and of a final chlorination tank, according to the traditional diagram of single-stage sewage treatment process. Biomass is oxidized in a reactor with agitator by the air blown by a compressor. The processed liquid is sent to the settler through an overflow. The sludge settling on settler bottom are recycled by are circulation pump into the oxidation tank.

The water flowing out of the settler is chlorinated and conveyed to a drain. Process control,data acquisition and supervision are automatically carried out by a microprocessor controller and by a specific control and supervision software that enables the remote control of various operational parameters.

Training Program:

The process unit enables to develop and analyze the following issues:

Purification efficiency versus the following parameters:

composition of water to be treated

residence time

organic load

pH in oxidation tank

concentration of dissolved oxygen

Automatic PID control

Plant supervision

Technical Data:

Framework of AISI 304 stainless steel with castors.

Feed tank with capacity of 700 l.

Cylindrical oxidation reactor of transparent methacrylate, with capacity of 300 l,including an agitator of AISI 304 stainless steel with geared motor and air diffuser of AISI 316 sintered stainless steel.

Settler of transparent methacrylate, with capacity of 150 l.

Feed tank for hypochlorite solution, with capacity of 20 l.

Chlorination tank of transparent methacrylate, with capacity of 6 l.

Magnetic drive feed gear pump, with body of AISI 316 stainless steel, flow-rate 0 to 60l/h.

Sludge recirculation magnetic drive gear pump, with body of AISI 316 stainless steel,flow rate 0 to 60 l/h.

Metering pump of sodium hypochlorite, flow rate of 0 to 1.5 l/h.

Diaphragm compressor with body of stainless steel, flow rate of 1.2 Nm /h.

Board-type microprocessor-controlled pH-meter, with range of 2 to 12 pH and 4-20 mA output signal.

Board-type microprocessor-controlled dissolved oxygen meter, with range of 0 to 10 ppm and 4-20 mA output signal

Flowmeter for measuring the feed flow rate of air to the reactor, with range of 0 to 1800 Nl/h.

Electronic flow transmitter for feed flow rate, with range of 0 to 60 l/hand 4 to 20 mA output signal.

Board-type electronic indicator of feed flow rate with range of 0 to 60 l/h.

Electronic flow transmitter for sludge re circulation flow rate with range of 0 to 60 l/h and 4to 20 mA output signal

Board-type electronic indicator of sludge re circulation flow rate with range of 0 to 60 l/h

ThermoresistancePt 100 with sheath of AISI 316 stainless steel

Board-typeelectronic temperature indicator

Switchboard,complying with EC conformity mark, including plant synoptic and ELCB

Emergencypushbutton

Plantsynoptic

Connectinglines and valves of AISI 304 and 316 stainless steel

Max. feed: 1kg/day of COD (1.7 g/l for a flow rate of 25 l/h).

An ENGLISHinstruction manual consisting of experimental procedures, block diagram etc.will be provided along with the Apparatus.

The wholeset-up is well designed and arranged on a rigid structure painted withindustrial PU Paint.

Innovative Two to Three-Stage Purification Process

The pilot plant employs a 2-3 stage reverse osmosis (RO) membrane filtration system for high-efficiency water treatment. Pre-filters, high-pressure pumps, and integrated flow meters ensure optimal removal of contaminants, delivering up to 99% purification efficiency. This process supports a reliable water recovery rate and consistent performance for diverse applications.

User-Friendly Operation with PLC Control

Featuring a PLC-based semi-automatic control system and digital display, the plant allows precise management and real-time monitoring of system parameters such as pressure, flow, and water quality. The automation grade reduces manual intervention and enhances operational safety and accuracy.

Durable, Modular Design for Versatility

Constructed from high-grade SS304/316 stainless steel, the skid-mounted, modular design ensures long service life (5-7 years, maintenance dependent) and easy installation. The compact footprint enables flexible placement, making it suitable for industrial, research, or educational environments.

FAQ's of Water Purification Pilot Plant:

Q: How does the Water Purification Pilot Plant achieve such high purification efficiency?

A: The plant uses a multi-stage reverse osmosis (RO) membrane filtration process, combined with pre-filters and a high-pressure pump, to remove up to 99% of contaminants from raw or drinking water. The system is precisely controlled by a PLC, ensuring consistent and optimal purification output.Q: What applications is this pilot plant best suited for?

A: It is designed for pilot testing, R&D projects, and educational demonstration purposes. Its robust and modular construction also makes it highly suitable for industrial or research water treatment needs in various sectors.Q: When should maintenance be performed to ensure the plant's longevity?

A: Routine maintenance should be performed as per the manufacturer's guidelines or based on usage intensity. Pre-filters and RO membranes should be inspected and replaced as necessary, which helps achieve the expected service life of 5-7 years.Q: Where can the Water Purification Pilot Plant be installed?

A: Thanks to its skid-mounted, modular design and compact dimensions (1800mm x 1200mm x 1800mm), the plant can be conveniently installed in laboratories, research institutes, factories, or educational facilities with standard electrical connections.Q: What is the process for using raw or drinking water as feed in this system?

A: Feed water enters through the inlet (operating at 1-4 bar pressure); it then passes through pre-filters and the RO membrane stages, where contaminants are efficiently removed. The integrated flow meter and digital display help track the purification process in real-time.Q: What are the main benefits of choosing this pilot plant for water treatment projects?

A: Key advantages include high purification efficiency, low noise operation, easy installation, low maintenance, and flexibility to support a range of pilot testing and R&D activities thanks to its modular and semi-automatic design.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Operation Lab. Category

Jaw Crusher

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Equipment Materials : SS

Material : Metal

Voltage : 220 Volt (v)

Power : 1000 Watt (w)

Froth Floatation Cell

Minimum Order Quantity : 1 Unit

Usage : For Laboratory

Equipment Materials : SS

Material : Metal

Voltage : 220 Volt (v)

Power : 500 Watt (w)

Cyclone Separator

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Equipment Materials : SS

Material : Metal

Voltage : 240 Volt (v)

Power : 500 Watt (w)

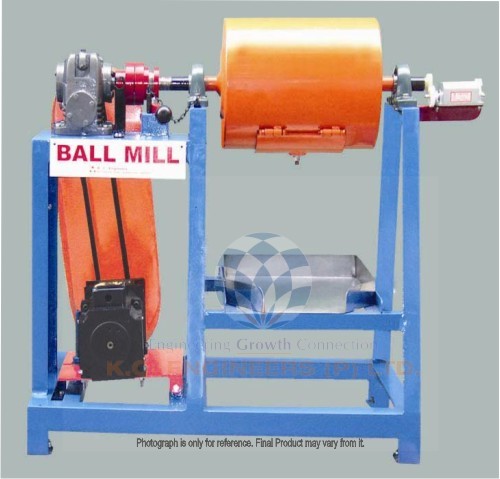

BALL MILL (Variable Speed)

Minimum Order Quantity : 1 Unit

Usage : For Laboratory

Equipment Materials : SS

Voltage : 220 Volt (v)

Power : 500 Watt (w)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free