Calibration of Pressure Gauges

Calibration of Pressure Gauges Specification

- Feature

- High Precision, Traceable Calibration, Portable Setup

- Voltage

- 220 V for digital equipment

- Accuracy

- 0.25% of FS

- Capacity

- Up to 1000 Bar

- Measurement Range

- 0 to 1000 Bar

- Model No

- PGC-2024

- Core Components

- Pressure Gauge, Reference Standard, Hand Pump

- Power Source

- Manual Operation / Electric for digital units

- Frequency

- 50 Hz

- Temperature Range

- -10C to +50C

- Automation Grade

- Manual/Semi-Automatic

- Equipment Materials

- Stainless Steel, Brass

- Type

- Pressure Gauge Calibration

- Usage

- Calibration Laboratories, Industrial Applications

- Display Type

- Analog/Digital

- Dimension (L*W*H)

- 350 x 250 x 150 mm (standard)

- Weight

- 2-8 kg (depending on configuration)

About Calibration of Pressure Gauges

Description :

Operationof Bourdon tube pressure gauge and a piston manometer working principle ofbourdon type pressure gauge, accurately fitting piston and cylinder of the piston without seals.

Technical Details :

- Bench Top Unit Will be provided

- Piston Manometer, Pressure piston of diameter of 12mm

- Hydraulic cylinder of dia.25mm &Length 225mm approx.

- Oil of Viscosity grade ( VG 32)

- Set Of Weights Weightholder 385g & 0.334 bar Pressure1X193g, 0.166bar

4x578g, 0.5bar

- Measuring Range 0to 2.5bar

- An instruction manual consisting ofexperimental procedures, block diagram etc. will be provided along with the Apparatus.

- Thewhole set-up is well designed and arranged on a rigid structure painted withindustrial PU Paint.

High-Precision and Certified Calibration

Our pressure gauge calibration systems utilize NABL/ISO-certified standards, ensuring accuracy and traceability in every measurement. The equipment is designed for rigorous calibration of analog and digital gauges up to 1000 Bar, with a resolution of 0.01 Bar for digital units. Overpressure protection and high environmental resistance (IP54) boost reliability in diverse operating conditions, presenting a top-tier solution for both laboratory and industrial environments.

Versatile and User-Friendly Design

Featuring 1/4" or 1/2" BSP/NPT connections, compatibility with air, oil, and water, and stainless steel/brass construction, this calibration setup is engineered for adaptability. The system supports both manual and electric (for digital units) operation and is supplied with a carrying case, test hoses, and adapters. The intuitive readout and portable setup allow for seamless on-site or in-lab usage, enhancing workflow efficiency.

FAQ's of Calibration of Pressure Gauges:

Q: How is the calibration of pressure gauges performed using this system?

A: Calibration is carried out by connecting the test gauge to the system using compatible BSP/NPT fittings. The included hand pump or electric actuator (for digital models) applies controlled pressure. The reference standard (NABL/ISO certified) serves as the benchmark. The process involves comparing the gauge reading with the reference value, documenting results, and adjusting if necessary.Q: What is the calibration validity period for these pressure gauges?

A: Each pressure gauge calibration performed with Model PGC-2024 has a calibration validity of one year from the date of issue. This ensures sustained measurement accuracy and compliance with industry standards.Q: When should I calibrate my pressure gauges?

A: Calibration is recommended annually or whenever gauges are suspected to be out of specification due to drift, external impacts, or process changes. Regular calibration maintains reliability and meets regulatory requirements for industrial and laboratory applications.Q: Where can this calibration equipment be used?

A: The calibration system is designed for use in both industrial facilities and calibration laboratories. Its portable form factor, environmental protection (IP54 for digital units), and robust accessories make it suitable for varied on-site or controlled laboratory environments.Q: What accessories are included with the pressure gauge calibration kit?

A: The kit is supplied with test hoses, fittings/adapters, and a carrying case, facilitating quick setup and safe transport. These accessories enhance convenience and versatility for a broad range of calibration scenarios.Q: How does overpressure protection work in this calibration setup?

A: The system is engineered with safety mechanisms capable of handling overpressure up to 150% of the full-scale range. This protection prevents damage to both the reference and test gauges during calibration, enhancing longevity and safety.Q: What benefits does NABL/ISO certified calibration provide?

A: NABL/ISO certification ensures that calibration results are traceable and internationally recognized. This increases credibility for manufacturers and exporters, supports compliance, and guarantees reliable, accurate measurements across a broad range of industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Process Control & Instrumentation Lab. Category

Interacting & Non Interacting System

Minimum Order Quantity : 1 Unit

Temperature Range : 40 Celsius (oC)

Material : Metal

Usage : Laboratory

Type : Interacting System

Equipment Materials : PU

TEMPERATURE CONTROL TRAINER (Computer Controlled System)

Minimum Order Quantity : 1 Unit

Temperature Range : 50 Celsius (oC)

Material : Metal

Usage : Laboratory

Type : Temperature Control

Equipment Materials : Copper

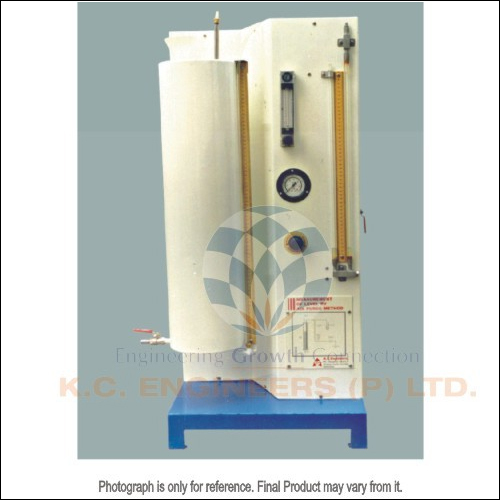

MEASUREMENT OF LEVEL BY AIR PURGE METHOD

Minimum Order Quantity : 1 Inch

Temperature Range : 50 Celsius (oC)

Material : Metal

Usage : Laboratory

DEAD WEIGHT PRESSURE GAUGE TESTER

Minimum Order Quantity : 1 Unit

Temperature Range : 90 Celsius (oC)

Material : Metal

Usage : Laboratory

Type : Gauge Tester

Equipment Materials : SS

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free