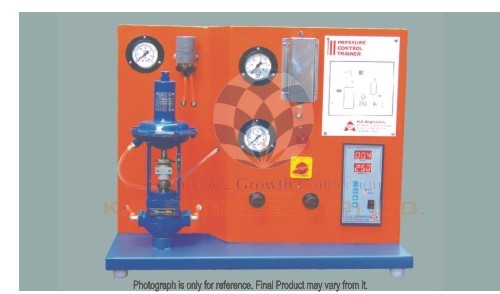

Pressure Control Trainer (Computer Controlled System)

Pressure Control Trainer (Computer Controlled System) Specification

- Usage

- Laboratory

- Voltage

- 220 Volt (v)

- Type

- Control Trainer

- Temperature Range

- 70 Celsius (oC)

- Display Type

- Digital

Pressure Control Trainer (Computer Controlled System) Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Central America, Africa, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

About Pressure Control Trainer (Computer Controlled System)

The setup consists of a process tank in which compressed air enters through a Pneumatic control valve. The pressure transmitter is fitted on the process tank. The air pressure in process tank is sensed by the transmitter and communicated to the digital indicating controller. This measured variable is compared with the Set Point by controller and output is generated and given to I/P converter, which in turn supply the 3-15 Psig pressure to vary the opening of the Pneumatic control valve to eliminate the error observed. As the opening of pneumatic control valve varies, the pressure in the Process Tank gets effected. This process goes on until the Set Point target is achieved. A ball valve is also provided in the process tank to disturb the system and to observe the effect of disturbance. These units along with necessary piping are supported in a well-designed housing and are fixed on base plate.

EXPERIMENTATION :

- To study the open loop or manual control

- To study the proportional control

- To study the two mode (P+I) control

- To study the two mode (P+D) control

- To study the three mode (PID) control

- To study the tuning of controller (Open loop method) using Zeigler-Nichols method.

- To study the stability of the system using the BODE PLOT.

- Auto Tuning

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Process Control & Instrumentation Lab. Category

Calibration of Pressure Gauges

Usage : Calibration Laboratories, Industrial Applications

Type : Pressure Gauge Calibration

Temperature Range : 10C to +50C

Equipment Materials : Stainless Steel, Brass

Interacting & Non Interacting System

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Type : Interacting System

Temperature Range : 40 Celsius (oC)

Equipment Materials : PU

Material : Metal

Level Control Trainer (Computer Controlled System)

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Type : Level Trainer

Temperature Range : 60 Celsius (oC)

Equipment Materials : Brass

Material : Metal

Control Valve Characteristics (Linear, Equal Perce

Minimum Order Quantity : 1 Unit

Usage : For Laboratory

Type : Valve

Temperature Range : 70 Celsius (oC)

Equipment Materials : Brass

Material : Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free