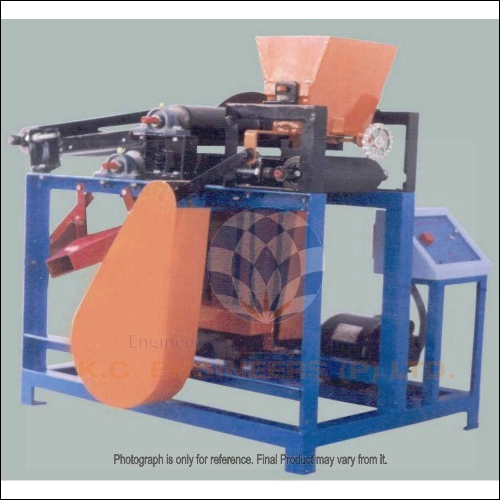

Magnetic Separator

Magnetic Separator Specification

- Voltage

- 220 Volt (v)

- Material

- Iron

- Power

- 1000 Watt (w)

- Usage

- For Laboratory

- Color

- Blue and Orange

- Equipment Materials

- SS

- Display Type

- Digital

Magnetic Separator Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Middle East, Central America, Africa, South America, Asia, North America

- Main Domestic Market

- All India

About Magnetic Separator

DESCRIPTION :Materials, that have different magnetic attractability, may be separated by passing them through a magnetic field. Most often, magnetic separation techniques are used to remove iron, steel or magnetic iron oxide from materials low in magnetic attractability. These devices operate in either a continuous or a cyclic manner. Continuous devices usually have a belt which moves over the lifting magnetic poles to carry the magnetize partials into a region of low or zero magnetic field, where they are released. The present set-up is of In-line lifting magnet type. The set-up consists of two belts moving separately in opposite direction at slow speed. Feed through a vibrating hopper is conveyed over first belt and allowed to pass near the second belt, which is under magnetic field. The magnetic field is generated by permanent magnet kept in a box. Magnetically inert material drops off the belt in a normal manner. Magnetic material is held on the belt, however, and finally drops off the belt as it leaves the magnetic field. Both the belts are fitted on the pullies and drived by an electric motor coupled with a reduction gearbox.

EXPERIMENTATION :

- To study the Principles and operation of a Magnetic Separator.

- To determine the efficiency of Magnetic Separator.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Operation Lab. Category

Jaw Crusher

Minimum Order Quantity : 1 Unit

Equipment Materials : SS

Material : Metal

Usage : Laboratory

Voltage : 220 Volt (v)

Power : 1000 Watt (w)

BALL MILL (With Three Prefixed Speeds)

Minimum Order Quantity : 1 Unit

Equipment Materials : Brass

Material : Metal

Voltage : 230 Volt (v)

Power : 1000 Watt (w)

Cyclone Scrubber

Minimum Order Quantity : 1 Unit

Equipment Materials : SS

Material : Metal

Usage : For Laboratory

Rotary Vacuum Filter

Minimum Order Quantity : 1 Unit

Equipment Materials : SS

Material : Iron

Usage : For Laboratory

Voltage : 220 Volt (v)

Power : 500 Watt (w)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS