EMULSION POLYMERISATION SET-UP

EMULSION POLYMERISATION SET-UP Specification

- Voltage

- 220 Volt (v)

- Material

- Metal

- Power

- 500 Watt (w)

- Usage

- Laboratory

- Color

- Red and Blue

- Equipment Materials

- SS

- Display Type

- Digital

EMULSION POLYMERISATION SET-UP Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Asia

- Main Domestic Market

- All India

About EMULSION POLYMERISATION SET-UP

DESCRIPTION :The set-up is used to carry out the emulsion polymerization involving polymerization of a unsaturated monomer like Styrene. Emulsion is of the type: oil in water, monomer is oil soluble & the initiator is water-soluble & an emulsifier is used to create a stable emulsion. Apparatus can be used to generate the kinetic data for emulsion polymerization under various operating conditions like temperature, emulsifier concentration etc. Polymerization is carried out under the atmosphere of air free nitrogen. The set-up consists of jacketed type SS reactor fitted with a variable speed agitator & baffles. Hot water from a digitally controlled water bath is circulated in the jacket using a pump. Metered quantity of nitrogen gas from a cylinder passes through a de-oxygenation column & allowed to enter in the reactor. Air has to be evacuated using a vacuum pump to create vacuum up to 30mm of Hg before passing the nitrogen supply. Initiator from reservoir is supplied to the reactor under pressure. Set-up is complete & self-contained with sampling ports.

EXPERIMENTATION :

The parameter studies are conducted involving studies of :

- Effect of RPM on conversion.

- Effect of Initiator concentration.

- Effect of monomer concentration

- Effect of emulsifier concentration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Reaction Engineering Lab. Category

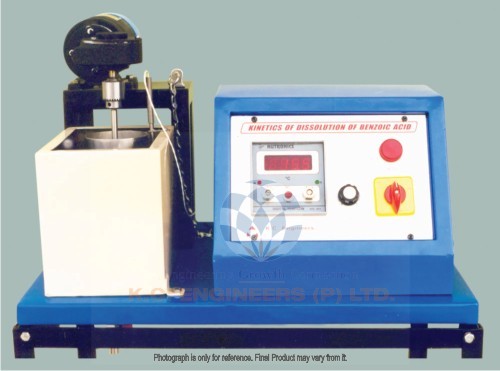

Kinetics of Dissolution of Benzoic Acid

Minimum Order Quantity : 1 Unit

Usage : For College and IIT

Equipment Materials : SS

Material : Metal

Voltage : 240 Volt (v)

Continuous Stirred Tank Reactor - Compressed Air F

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Equipment Materials : SS

Material : Metal

Voltage : 240 Volt (v)

SPINNING BASKET REACTOR - Compressed Air Feed System

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Equipment Materials : Brass

Material : Metal

Type : Compressed

CHEMICAL REACTOR SERVICE UNIT- Constant Head Feed System

Minimum Order Quantity : 1 Unit

Usage : Laboratory Parts

Equipment Materials : SS

Material : Metal

Type : Head Feed System

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free