FLUID MIXING & POWER CONSUMPTION IN AGITATED VESSEL

FLUID MIXING & POWER CONSUMPTION IN AGITATED VESSEL Specification

- Usage

- For Laboratory

- Operate Method

- Manual

- Material

- Metal

- Equipment Materials

- SS

FLUID MIXING & POWER CONSUMPTION IN AGITATED VESSEL Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Per Day

- Delivery Time

- Week

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Middle East, South America, Western Europe, Asia, Central America

- Main Domestic Market

- All India

About FLUID MIXING & POWER CONSUMPTION IN AGITATED VESSEL

DESCRIPTION For a processing vessel to be effective the volume of fluid circulated by the impellers must be sufficient to sweep out the entire vessel in a reasonable time The velocity of the stream leaving the impeller must be sufficient to carry the current to the remotest parts of the tank Liquids are most often mixed in some kind of tanks or vessels usually cylindrical in form and with a vertical axis Tank bottom is rounded to eliminate regions into which the fluid currents would not penetrate In the present setup mixing is done with the help of stirrer The stirrer is complete with SS Impeller with SS Shaft coupled to FHP DC motor The speed of agitator can be varied with the help of Thyristor controlled DC Drive and power consumption is measured by Digital Voltmeter Digital Ammeter Four replaceable baffles are provided to prevent swirling One 4bladded propeller and one 6bladded turbine are provided which are interchangeable Drain valve is also provided at the bottom Effectiveness of power consumption in fluid mixing can be performed with and without baffles hence increasing the range of experimentation The whole setup is mounted on a rigid MS frame structure EXPERIMENTATION To plot Power number Vs Reynolds number for the given set of impeller with baffled unbaffled mixing To study the mixing characteristics of give solidliquid mixture

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Mechanical Operation Lab. Category

Thickner Instroments

Minimum Order Quantity : 1 Piece

Equipment Materials : SS

Usage : For Industry

Material : Iron

Power : 500 Watt (w)

Voltage : 230 Volt (v)

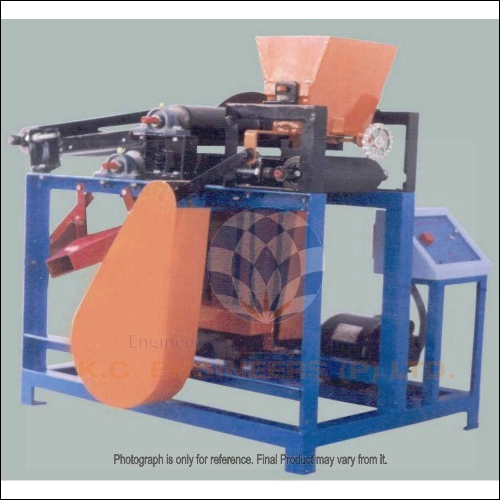

Roll Crusher

Minimum Order Quantity : 1 Unit

Equipment Materials : Brass

Usage : Laboratory

Material : Metal

Power : 1000 Watt (w)

Voltage : 240 Volt (v)

Magnetic Separator

Minimum Order Quantity : 1 Unit

Equipment Materials : SS

Usage : For Laboratory

Material : Iron

Power : 1000 Watt (w)

Voltage : 220 Volt (v)

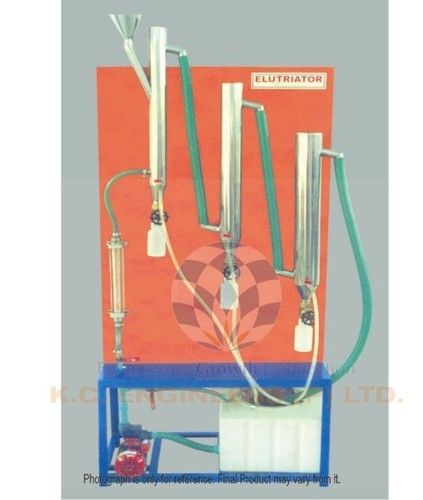

ELUTR IATOR

Minimum Order Quantity : 1 Unit

Equipment Materials : PU

Usage : For Laboratory

Material : Metal

Power : 500 Watt (w)

Voltage : 220 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free