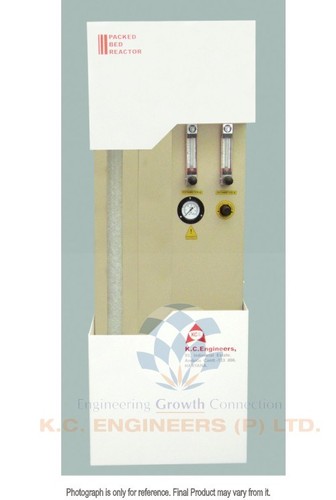

CHEMICAL REACTOR SERVICE UNIT- Compressed Air Feed System

CHEMICAL REACTOR SERVICE UNIT- Compressed Air Feed System Specification

- Material

- Metal

- Usage

- Laboratory

- Operate Method

- Manual

- Equipment Materials

- Reactor

- Display Type

- Analog

CHEMICAL REACTOR SERVICE UNIT- Compressed Air Feed System Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Central America, Africa, Middle East, South America, Asia

- Main Domestic Market

- All India

About CHEMICAL REACTOR SERVICE UNIT- Compressed Air Feed System

DESCRIPTION :This set-up is designed to conduct experiments on different types of chemical reactors on the sameservice unit. Different types of reactors i.e. Continuously Stirred Tank Reactor (CSTR), Plug FlowTubular Reactor (Coiled Tube Type) and Batch Reactor (which will be supplied on extra cost) as separateunits can be installed on the service unit individually one at a time for conducting experiments. Basicallythis range of small-scale chemical reactors represents the most common types of chemical reactor foundin industry. The reactors use the saponification reaction between ethyl acetate and sodium hydroxide.This provides a well-understood and safe reaction for the students to investigate the different reactortypes.Each reactor, mounted on a base plate can be attached to the service unit. The appropriate services suchas feed circulation, instrumentation for and temperature measurement are connected to the reactor, and itthen becomes operational. This service unit comprises feed tanks, rotameters for flow measurement ofreactant etc. Compressed air is used for feed circulation. These all things are mounted on a compact andwell-designed base for bench mounting. This is self-contained bench top service unit to accommodate thereactors, one at a time, for conducting experiments on the same unit.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Reaction Engineering Lab. Category

ISOTHERMAL PLUG FLOW TUBULAR REACTOR (Coiled Tube Type) - Compressed Air Feed System

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : Metal

Equipment Materials : SS

Voltage : 220 Volt (v)

Power : 250 Watt (w)

ISOTHERMAL CONTINUOUS STIRRED TANK REACTOR - Constant Head Feed System

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Material : Metal

Equipment Materials : Brass

Voltage : 240 Volt (v)

Power : 250 Watt (w)

PACKED BED REACTOR - Peristaltic Pump Feed System

Minimum Order Quantity : 1 Unit

Usage : Laboratory

Material : Metal

Equipment Materials : SS

CASCADE CONTINUOUS STIRRED TANK REACTOR - Peristaltic Pump Feed System

Minimum Order Quantity : 1 Unit

Usage : For Laboratory

Material : Metal

Equipment Materials : SS

Voltage : 240 Volt (v)

Power : 1000 Watt (w)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free