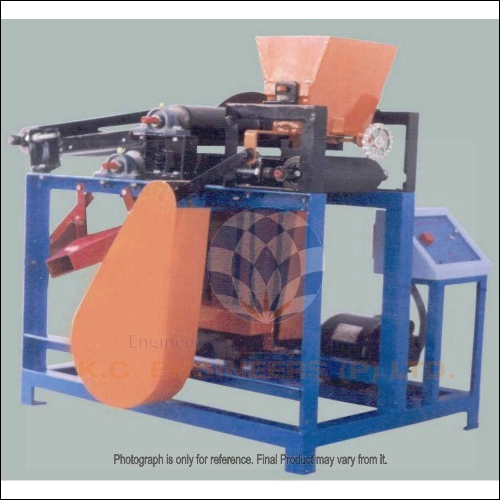

Froth Floatation Cell

Froth Floatation Cell Specification

- Power

- 500 Watt (w)

- Usage

- For Laboratory

- Voltage

- 220 Volt (v)

- Material

- Metal

- Equipment Materials

- SS

- Type

- Flotation Cell

Froth Floatation Cell Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Asia

- Main Domestic Market

- All India

About Froth Floatation Cell

Mixed liberated particles can be separated from each other by floatation if there is sufficient difference in their wettability. The floatation process operates by preparing a water suspension of a mixture of relatively finely sized solids. This is usually done in an agitated chamber open at the top. Fine bubbles of air are then dispersed through the agitated suspension to form a froth that rises to the top of the chamber. Particles that are radially wetted by water (hydrophilic) tend to remain in the water suspension. Those particles that are not easily wetted (hydrophobic) tend to be collected at the air bubble-water interface and rise to the surface attached to air bubbles. Thus differences in the surface chemical properties of the solids are the basis for separation.The set up consists of a agitated chamber open at the top. In the chamber, an impeller coupled to a shaft is fixed in a stationary diffuser. Low-pressure air is allowed to enter in the stationary diffuser through the air passage provided with the agitator. The collector coated mineral particles adhere to the rising bubbles and are carried to the top of the cell to be removed in the froth product.

EXPERIMENTATION :

- To study the performance of Froth Flotation Cell.

- To find % recovery of mineral in froth from a standard mixture.

Advanced Laboratory Separation

Engineered for laboratory environments, this Froth Flotation Cell facilitates effective separation of minerals and materials using the well-established flotation method. Its robust construction from stainless steel ensures durability and consistent operation.

User-Friendly Design

The flotation cell is designed for straightforward setup and maintenance, making laboratory procedures more efficient. With precise power and voltage ratings, it provides the control needed for accurate and repeatable results.

Trusted Indian Manufacturer

Our equipment is manufactured and exported from India, adhering to global quality standards. We ensure each product meets stringent requirements for laboratory use, supported by responsive after-sales service and technical assistance.

FAQs of Froth Floatation Cell:

Q: How does the Froth Flotation Cell operate in a laboratory setting?

A: The Froth Flotation Cell works by agitating a mixture of water, chemicals, and minerals, creating bubbles that selectively attach to ore particles. This separates valuable minerals from the rest, allowing researchers to analyze and recover specific components.Q: What materials are used in the construction of this flotation cell?

A: This laboratory flotation cell is constructed using high-quality metal and stainless steel (SS), ensuring excellent durability, corrosion resistance, and long-term reliability for repeated laboratory use.Q: When is the Froth Flotation Cell suitable for use?

A: The equipment is ideal for laboratory-based mineral processing, research experiments, and educational demonstrations. It is best suited when accurate material separation and analysis are required.Q: Where is your Froth Flotation Cell manufactured and supplied from?

A: Our Flotation Cell is manufactured, supplied, and exported from India. It is distributed globally to laboratories and research institutes needing reliable mineral processing equipment.Q: What is the process involved in froth flotation using this cell?

A: The process involves mixing sample material with water and reagents in the cell, then introducing air to generate froth. The selective attachment of bubbles to desired mineral particles enables efficient separation for analysis.Q: How can users benefit from using this laboratory flotation cell?

A: Researchers and lab technicians benefit by achieving precise, repeatable separation results. The equipments energy efficiency, robust build, and ease of use enhance workflow and experimental outcomes in laboratory studies.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Operation Lab. Category

Roll Crusher

Minimum Order Quantity : 1 Unit

Material : Metal

Equipment Materials : Brass

Usage : Laboratory

Voltage : 240 Volt (v)

Power : 1000 Watt (w)

Magnetic Separator

Minimum Order Quantity : 1 Unit

Material : Iron

Equipment Materials : SS

Usage : For Laboratory

Voltage : 220 Volt (v)

Power : 1000 Watt (w)

Screw Conveyor (With Three Prefixed Speeds)

Minimum Order Quantity : 1 Unit

Material : Iron

Equipment Materials : Brass

Usage : For College Labs

Voltage : 220 Volt (v)

Power : 500 Watt (w)

Cyclone Separator

Minimum Order Quantity : 1 Unit

Material : Metal

Equipment Materials : SS

Usage : Laboratory

Voltage : 240 Volt (v)

Power : 500 Watt (w)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS