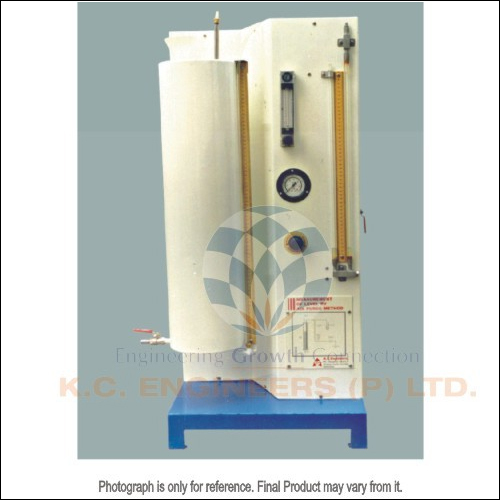

MEASUREMENT OF LEVEL BY AIR PURGE METHOD

MEASUREMENT OF LEVEL BY AIR PURGE METHOD Specification

- Usage

- Laboratory

- Color

- White and Blue

- Material

- Metal

- Voltage

- 15 Volt (v)

- Temperature Range

- 50 Celsius (oC)

MEASUREMENT OF LEVEL BY AIR PURGE METHOD Trade Information

- Minimum Order Quantity

- 1 Inch

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Inch Per Day

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Africa, Middle East, South America, Asia, Central America, North America

- Main Domestic Market

- All India

About MEASUREMENT OF LEVEL BY AIR PURGE METHOD

The apparatus is based on the principle that when compressed air is purged into the pipe, the liquid within the pipe is displaced by air pressure equal to the hydrostatic force of the liquid in the tank or vessel. The apparatus consists of a pipe lowered into the water tank to a point about 1 above the bottom of the tank. This tank is fitted with a scale to get direct reading of liquid in the tank. Water tank is supplied with the provision of changing the height of the liquid in the tank. For this purpose proper arrangement is provided. Compressed air is supplied to the apparatus and Pressure Regulator acts as an Air Purging Valve. Pressure required for the set-up is maximum 0.25 kg/cm. Pressure regulator, when operated, gives a constant flow of air at constant pressure and it is observed by seeing the bubble coming out from bubbler pipe which is dipped in water tank. A U Tube manometer is connected separately to the upper end of the bubbler pipe. The system operates by building up a pressure in the feed line until the air escapes and the flow stabilizes. The pressure in the bubbler pipe necessary to cause the flow is just negligibly higher than the liquid head over the bubbler pipe. Therefore, the air feed must be available at a pressure slightly higher than the maximum head to be measured. The pressure measured by the manometer gives the water level in terms of head. All components are assembled on MS Structure and fitted on a base plate to form a table top set-up.

EXPERIMENTATION :

- To study the working of Air Purge Method.

- To determine the height of the liquid in the tank using Air Purge Method.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Process Control & Instrumentation Lab. Category

Interacting & Non Interacting System

Minimum Order Quantity : 1 Unit

Type : Interacting System

Temperature Range : 40 Celsius (oC)

Usage : Laboratory

Material : Metal

Equipment Materials : PU

Flow Control Trainer (Computer Controlled System)

Minimum Order Quantity : 1 Unit

Type : Flow Control

Temperature Range : 60 Celsius (oC)

Usage : Laboratory

Material : Metal

Equipment Materials : Brass

Time Constant of Manometer

Minimum Order Quantity : 1 Unit

Type : Constant of Manometer

Temperature Range : 60 Celsius (oC)

Usage : Laboratory

Material : Metal

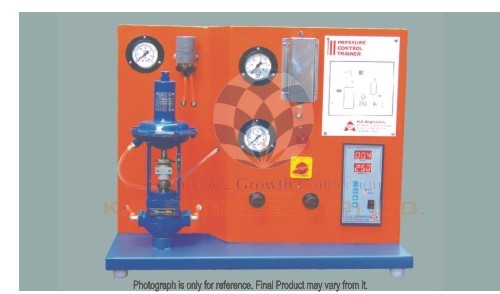

Pressure Control Trainer (Computer Controlled System)

Minimum Order Quantity : 1 Unit

Type : Control Trainer

Temperature Range : 70 Celsius (oC)

Usage : Laboratory

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free