Parallel Flow/Counter Flow Heat Exchanger

Parallel Flow/Counter Flow Heat Exchanger Specification

- Model No

- CF/PHX-100

- Capacity

- Up to 10000 kCal/hr

- Accuracy

- 1C

- Measurement Range

- 0C to 150C

- Frequency

- 50 Hz

- Core Components

- Heat Exchanger Tubes, Temperature Sensors

- Voltage

- 230 V

- Power Source

- Electric

- Temperature Range

- Ambient to 150C

- Automation Grade

- Manual

- Feature

- High Efficiency, Modular Design

- Equipment Materials

- Stainless Steel, Copper

- Type

- Parallel Flow / Counter Flow Heat Exchanger

- Usage

- Lab Experiment, Chemical Engineering Study

- Display Type

- Analog

- Dimension (L*W*H)

- 1100 x 500 x 800 mm

- Weight

- 35 kg

- Noise Level

- <70 dB

- Maintenance Requirement

- Low; easy tube cleaning access

- Tube Bundle Type

- Fixed tube sheet or floating head

- Heat Transfer Medium

- Water, Oil, Steam, Air, Glycol (customizable)

- Surface Area

- 1 m² to 25 m², selectable

- Working Pressure

- Up to 16 bar

- Design Standard

- ASME, TEMA, ISO Certified

- Ambient Operating Temperature

- 0°C to 50°C

- Number of Passes

- Single, Double, or Multipass as per selection

- Inlet/Outlet Connection

- Standard flange or threaded coupling

- Paint Finish

- Epoxy coated / Powder coated

- Mounting Type

- Floor Mounted/Skid Mounted/Wall Mounted

About Parallel Flow/Counter Flow Heat Exchanger

Application Method and Areas of Use

The Parallel Flow/Counter Flow Heat Exchanger is applied via standard flange or threaded coupling connections and is available in floor, skid, or wall-mounted configurations. Its expansive surface area supports efficient heat exchange for water, oil, steam, air, and glycol. Best used in laboratory experiments and chemical engineering studies, its modular design allows for versatility across mounting surfaces and customizable heat transfer mediums, making it suited for rigorous academic and industrial applications.

FOB Port, Packaging and Certifications Information

Charge your logistics with reliable transport services from Indias major FOB ports. This heat exchanger is securely shipped in protective packaging, ensuring product integrity during transit. Each unit comes with preeminent certifications including ASME, TEMA, and ISO, guaranteeing quality and safety standards. Secure shipping processes and adherence to international regulations ensure swift, uncompromised delivery for exporters, manufacturers, and suppliers.

FAQs of Parallel Flow/Counter Flow Heat Exchanger:

Q: How is the Parallel Flow/Counter Flow Heat Exchanger maintained for optimal performance?

A: This equipment is designed for low maintenance, with easy tube cleaning access. Regular inspection and periodic cleaning of the tube bundle are recommended to sustain its high efficiency and accuracy.Q: What types of heat transfer mediums can be used with this heat exchanger?

A: The heat exchanger supports water, oil, steam, air, and glycol as transfer mediums. Customization is available based on specific application requirements.Q: Where can this heat exchanger be mounted and what are the available options?

A: Mounting options include floor, skid, or wall installation, offering flexibility for space constraints and operational preferences in labs or industrial setups.Q: When should users consider choosing single, double, or multipass configurations?

A: The number of passes should be selected based on desired heat transfer rates and specific process requirements. Multipass designs enhance thermal efficiency for demanding applications.Q: What certifications does the Parallel Flow/Counter Flow Heat Exchanger hold?

A: It is certified to ASME, TEMA, and ISO standards, verifying its quality, safety, and international compliance.Q: Which process benefits most from the modular design of this heat exchanger?

A: The modular design enables seamless adaptation for various laboratory experiments and chemical engineering studies, facilitating convenient setup, operation, and future expansion.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Engineering Lab Category

Heat Transfer Coefficient of Composite Wall apparatus

Minimum Order Quantity : 1 Unit

Accuracy : 0.5C for temperature measurement

Usage : Measurement of heat transfer coefficient through composite walls

Measurement Range : Heat Transfer Rate: Up to 40 W

Capacity : 1 Experiment at a time

Weight : Approx. 30 kg

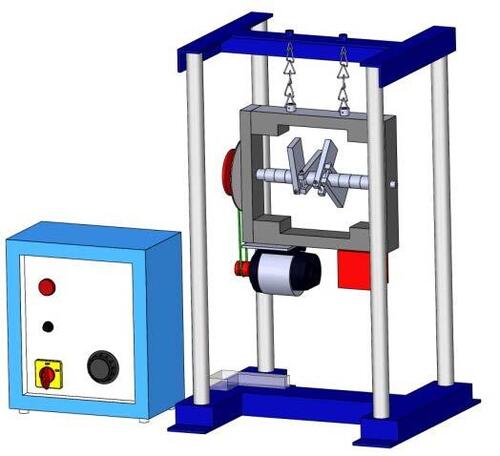

Static and Dynamic Balancing Apparatus

Minimum Order Quantity : 1 Unit

Accuracy : 1% of Reading

Usage : Static and Dynamic Balancing of Rotors

Measurement Range : Up to 1 kg Eccentric Mass

Capacity : 1 kg

Weight : Approx. 25 kg

Kaplan Turbine

Minimum Order Quantity : 1 Unit

Accuracy : 1%

Usage : Hydroelectric Power Generation

Measurement Range : 10 m/s to 300 m/s

Capacity : 1 MW 100 MW

Weight : 2500 kg

JET IMPACT APPARATUS

Minimum Order Quantity : 1 Piece

Accuracy : High accuracy with calibrated scale

Usage : Educational laboratory, for studying impact of jet

Measurement Range : Force range up to 10 N

Capacity : 5 to 10 Liters (Tank capacity)

Weight : 2530 kg (approx.)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free