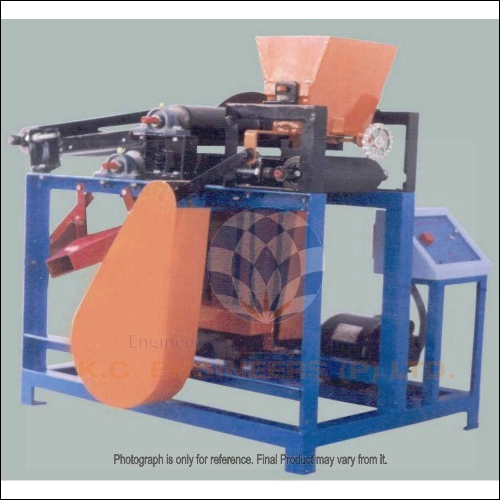

Thickner Instroments

Price 25000 INR/ Piece

Thickner Instroments Specification

- Power

- 500 Watt (w)

- Color

- Blue and Silver

- Usage

- For Industry

- Material

- Iron

- Voltage

- 230 Volt (v)

- Equipment Materials

- SS

Thickner Instroments Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 2-4 Week

- Main Export Market(s)

- Western Europe, Australia, Eastern Europe, Central America, Africa, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

About Thickner Instroments

Industrial sedimentation operations may be carried out batch wise and continuously in equipment called thickener. The equipment is a cylindrical tank with openings for a slurry feed and product draw off. The tank is filled with dilute slurry and slurry is permitted to settle. Continuous thickeners are large diameter, shallow depth tanks with slowly revolving rakes for removing the sludge. The slurry is fed at the center of the tank. Around the top edge of the tank is a clear liquid overflow. The rake serves to scrap the sludge towards the center of the bottom for discharge. The motion of the rake also stirs only the sludge layer. This gentle stirring aids in water removal from the sludge. The set-up consists of several basic components: a tank to contain the slurry, feed piping and a feed well to allow the feed stream to enter the tank, a rotating rack mechanism to assist in moving the concentrated solids to the withdrawal points, an underflow solids-withdrawal system and an overflow launder. A feed tank, feed pump, and feed tank agitator is provided. A bin for collecting concentrated material is also provided.

EXPERIMENTATION :

- To study the working of continuous type thickener.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Operation Lab. Category

Water Purification Pilot Plant

Equipment Materials : Stainless Steel (SS316/SS304)

Usage : Industrial/Research Water Treatment

Voltage : 220380 V

Type : Water Purification Pilot Plant

Filtration Pilot Plant

Equipment Materials : Stainless Steel (SS 304/316)

Usage : Pilot scale process filtration testing

Voltage : 220240V

Type : Filtration Pilot Plant

Magnetic Separator

Minimum Order Quantity : 1 Unit

Equipment Materials : SS

Usage : For Laboratory

Voltage : 220 Volt (v)

Material : Iron

Roll Crusher

Minimum Order Quantity : 1 Unit

Equipment Materials : Brass

Usage : Laboratory

Voltage : 240 Volt (v)

Material : Metal

Type : Crusher

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free