TWO STAGE RECIPROCATING AIR COMPRESSOR

TWO STAGE RECIPROCATING AIR COMPRESSOR Specification

- Core Components

- Compressor Block, Motor, Pressure Switch, Air Receiver

- Measurement Range

- upto 12 bar (Max Pressure)

- Voltage

- 220-240 / 380-415 V

- Model No

- Varies (e.g., TS-150, TS-200, etc.)

- Automation Grade

- Semi-Automatic

- Frequency

- 50 Hz

- Temperature Range

- Ambient up to 50C

- Power Source

- Electric

- Capacity

- 4 to 22 HP

- Feature

- High Efficiency, Low Noise, Heavy Duty Operation

- Equipment Materials

- Cast Iron

- Type

- Two Stage Reciprocating Air Compressor

- Usage

- Industrial, Workshop, Garage

- Display Type

- Analog

- Dimension (L*W*H)

- 1800 x 600 x 1200 mm (approx.)

- Weight

- 350-550 kg (depending on model)

- Maximum Pressure

- 12 kg/cm² (175 psi)

- Receiver Capacity

- 160 - 500 Litres

- Motor Power

- 3 - 15 kW

- Number of Cylinders

- 2

- Cooling Method

- Air Cooled

- Noise Level

- <80 dB(A)

- Drive Type

- V-Belt Driven

- Lubrication Type

- Splash Lubrication

- Air Displacement

- 250 - 1100 LPM (litres per minute)

- Stages

- 2 Stage

- Pump Speed

- 900-1200 RPM

About TWO STAGE RECIPROCATING AIR COMPRESSOR

Versatile Excellence for Demanding Applications

The Two Stage Reciprocating Air Compressor is perfectly suitable for industrial operations, workshops, and garages. Built from durable cast iron, it is designed to withstand high-pressure tasks and continual heavy-duty use. Its dual-stage configuration ensures optimal performance, and the air-cooled mechanism keeps the system running efficiently even in ambient temperatures up to 50C. Whether you're supporting tooling, spray painting, or mechanical tasks, this compressor meets the needs of professional and commercial settings seamlessly.

Professional Sample Policy, Payment Terms, and Transport

As a respected exporter, manufacturer, and supplier in India, we prioritize the global export market by offering a transparent sample policy and secure payment terms. All units are certified for industrial safety and efficiency, ensuring maximum reliability. We handle transportation with care, and competitive sale prices are provided to support client requirements. Choose us for a smooth transaction, certified quality, and timely delivery of Two Stage Reciprocating Air Compressors worldwide.

FAQ's of TWO STAGE RECIPROCATING AIR COMPRESSOR:

Q: How does the two stage design benefit industrial operations?

A: The two stage configuration allows the compressor to deliver higher maximum pressures (up to 12 kg/cm2) efficiently, making it ideal for demanding industrial tasks that require consistent air supply and enhanced durability.Q: What materials are used in constructing the compressor?

A: Our compressors are constructed with premium cast iron, ensuring robust performance, longevity, and reliability under continuous heavy-duty operation.Q: Where can the Two Stage Reciprocating Air Compressor be used?

A: This compressor is highly versatile and suitable for various settings including industrial facilities, workshops, and automotive garages, where high efficiency and reliability are required.Q: What are the core components of this air compressor?

A: The main components include the compressor block, electric motor, pressure switch, and a heavy-duty air receiver, all contributing to stable and safe operation.Q: What are the accepted payment terms and sample policy for export purchases?

A: We offer flexible payment terms and a clear sample policy for international buyers. Please contact our sales team for detailed information based on your order size and destination.Q: How is transportation and delivery managed for export orders?

A: We ensure safe transportation and timely delivery for all orders. Items are carefully packaged and shipped according to export regulations, with competitive sale prices ensuring value for clients overseas.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Engineering Lab Category

Cam Analysis Machine

Minimum Order Quantity : 1 Unit

Feature : Interchangeable cams and followers, speed measurement

Usage : Study of camfollower dynamics and motion analysis

Power Source : Electric motordriven

Capacity : Single cam and follower analysis

Temperature Range : Ambient

Heat Transfer Coefficient of Composite Wall apparatus

Minimum Order Quantity : 1 Unit

Feature : Visual heat flow analysis, individual layer temperature measurement

Usage : Measurement of heat transfer coefficient through composite walls

Power Source : Electric

Capacity : 1 Experiment at a time

Temperature Range : Ambient to 100C

Screw Jack Apparatus With Weights

Minimum Order Quantity : 1 Unit

Feature : Demonstrates Principle of Screw Jack, Educational Purpose

Usage : Laboratory Demonstration & Mechanical Advantage Experiments

Power Source : Manual Operation

Capacity : 50 kg (typical)

Temperature Range : Ambient

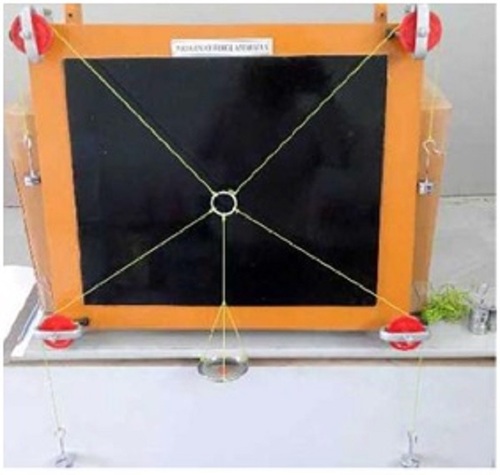

Universal Force Table Normal

Minimum Order Quantity : 1 Unit

Feature : Low friction pulleys, precise angular markings

Usage : Educational physics experiments on forces and equilibrium

Power Source : Manual (No power required)

Capacity : Normal laboratory use

Temperature Range : Ambient

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS